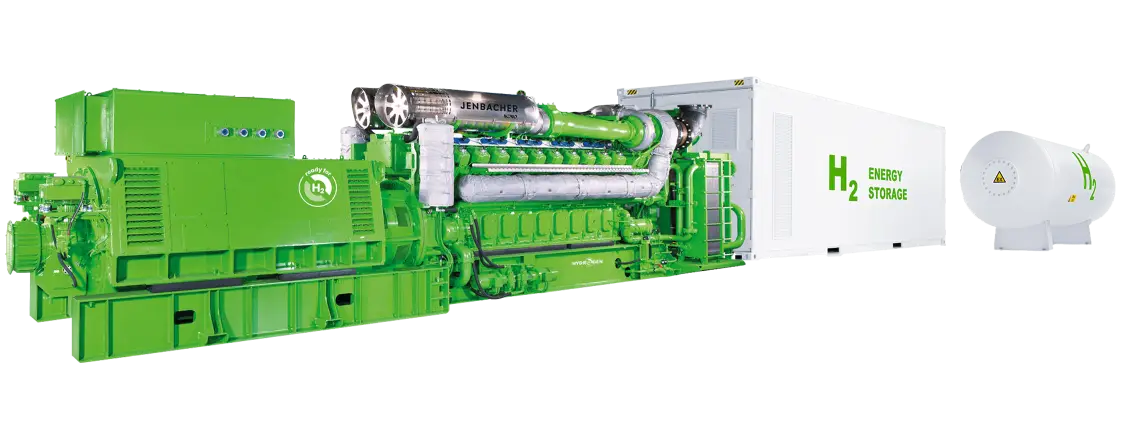

INNIO Jenbacher is launching our “Ready for H2” portfolio, which includes the first Jenbacher H2-engines.

Jenbacher Type 4 gas engines now are available as H2-engines that can run on 100% hydrogen. As of 2022, Jenbacher gas engines will be offered with the option to operate with up to 25% (volume) of hydrogen in the pipeline gas. Plus, all “Ready for H2” units and most of the currently installed Jenbacher natural gas-fueled engines can be converted to operate on 100% hydrogen when hydrogen becomes more readily available.

The INNIO Jenbacher gas engine portfolio is “Ready for H2.” Jenbacher Type 4 engines, with:

an output of 530, 710 and 890 kW

are available now as H2-engines

100% hydrogen

for operation

Alternatively, those engines are available as dual gas engines that can operate on 100% hydrogen, 100% natural gas or mixtures of natural gas and hydrogen. As of 2022, INNIO Jenbacher natural gas engines will be offered with the option to operate with up to 25% (volume) of hydrogen in the pipeline gas. In addition, all “Ready for H2” gas engines and most of the already installed Jenbacher gas engines can be converted to 100% hydrogen operation when hydrogen becomes more readily available.

As a key enabler and an integral part of the energy transition

INNIO is preparing for a climate-neutral, greener and more secure energy future.

Right now,

more than 8,500

INNIO Jenbacher gas engines

About half of the engines in the field—already operate on renewable carbon-neutral gases such as biogas, landfill gas and biomethane.

With more than 30 years of experience in the conversion of hydrogen-rich fuels into electricity, INNIO believes green hydrogen will be a major part of the world’s future energy mix. The reason: Green hydrogen produced from volatile renewable power (wind and solar) can be stored as energy in large amounts over longer timeframes, making renewable power dispatchable and fossil fuels replaceable. With the option to readily convert Jenbacher gas engines from natural gas to hydrogen operation, INNIO is providing a CO2-free solution in support of the energy transition.

The challenge ahead

With ongoing climate change, countries and organizations are developing a multitude of scenarios that detail how global warming can be slowed. Each of these scenarios calls for drastically reducing or completely phasing out fossil fuels and increasing reliance on renewable energy, predominantly wind and solar. These sources have low generation costs but are not available all the time. Oversupply and undersupply need to be balanced out—a major challenge for producers in the coming years. The solution is storage, but short-term storage over a few hours with batteries is not enough; large, long-term storage in the TWh-size range is needed. This can only be done with hydrogen.

The hydrogen solution

Solving the storage challenge is an essential part of the energy transformation from fossil fuels to renewable energy. Using power-to-gas (P2G) technology, green hydrogen is produced by converting renewable power like wind and solar to the energy storage product hydrogen. Unlike electricity, hydrogen can be stored long term in tanks or in large quantities in underground caverns—similar to natural gas—over months or seasons.

Large hydrogen networks are under development to transport and distribute hydrogen to end consumers, and hydrogen also can be added to the existing natural gas network with quantities:

of up to 20%

(volume) and perhaps

up to 30%

(volume) in the future

Soon, we could see pipeline natural gas provided with a hydrogen content as constant or frequently changing between 0 and 20% (volume).

INNIO is committed to leading the deployment of H2-engines, which will facilitate the acceleration and transformation from fossil fuels to renewable energy sources. While hydrogen as a fuel could be used across all sectors including industry, transportation and construction, the use of hydrogen in the energy sector will be essential to replace fossil natural gas. Using green hydrogen for re-electrification should always have priority for combined heat and power, because this application can achieve 90% hydrogen fuel utilization.

Initially, green hydrogen produced with P2G technology will be expensive, and the volume produced will be limited. During this transitional stage—as research focused on green hydrogen technologies continues—blue hydrogen produced from natural gas with Carbon Capture Utilization and Storage (CCUS) could play a role and accelerate the transition.

A history of innovation

The Jenbacher product line has more than 30 years of experience with engines running on high hydrogen fuels, and the first Jenbacher 150 kW pilot engine ran on 100% hydrogen at a demonstration plant in northern Germany 20 years ago! Two decades later, in 2020, after a number of additional demonstration projects, INNIO and HanseWerk Natur demonstrated the world’s first 1 MW hydrogen engine using variable hydrogen/natural gas mixtures, including 100% hydrogen, on a Jenbacher J416 gas engine.

These installations can be found on all continents—and islands from Japan to Hawaii—with special versions of Jenbacher gas engine Types 2, 3, 4 and 6. Typically, these hydrogen-rich fuels are available at low pressure and therefore are ideally suited for use in gas engines because the required fuel gas pressure is only approximately 100 mbar(g). These fuels typically have a relatively constant fuel composition with a low rate of change.

Today, INNIO’s 90

hydrogen-rich fuel projects

in 28

countries

more than 250 MW

in total

These installations can be found on all continents—and islands from Japan to Hawaii—with special versions of Jenbacher gas engine Types 2, 3, 4 and 6. Typically, these hydrogen-rich fuels are available at low pressure and therefore are ideally suited for use in gas engines because the required fuel gas pressure is only approximately 100 mbar(g). These fuels typically have a relatively constant fuel composition with a low rate of change.

We’re ready for H2!

INNIO Jenbacher “Ready for H2” natural gas engines offer operators investment security with the added benefit that the existing infrastructure can be converted to hydrogen and converted in a way that is CO2-free. With INNIO Jenbacher’s hydrogen expertise, installing a “Ready for H2”-designed natural gas power plant today will help reduce future hydrogen conversion costs.