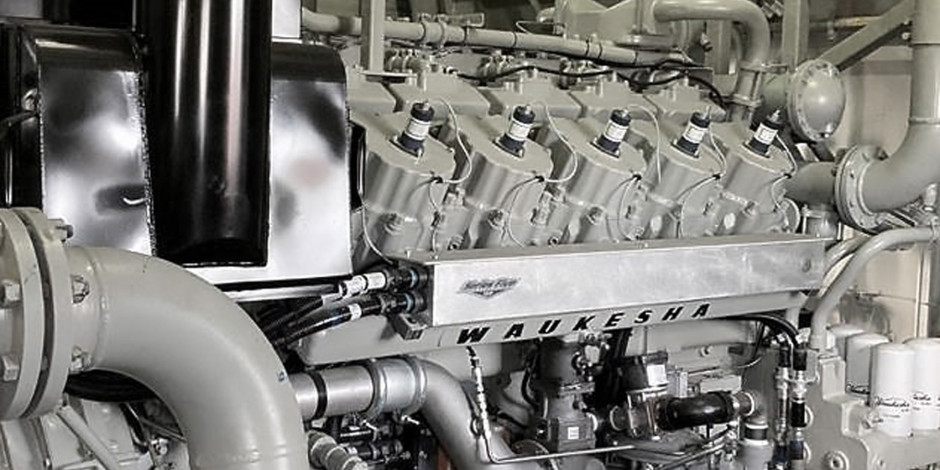

As the largest coalbed methane (CBM) producer in Alberta, Ember Resources continues to grow its Western Canada footprint. When a Canadian grant program provided incentives for station emissions reductions, Ember knew its proposed project in the Horseshoe Canyon region, which holds nearly 180 million cubic feet of untapped CBM, would need to meet low emissions, noise attenuation, high air quality, and stringent safety recommendations. The answer: an upgrade from INNIO’s Waukesha product line.

Waukesha’s assistance with government program navigation, combined with their technical engineering support, was nothing less than exceptional. Ember relied on Waukesha to help lay out technical details required throughout the government program application as well as equipment retrofit processes—a challenge that the Waukesha team knocked out of the park.

Jay Befus, Emissions Compliance and Rotating Equipment Specialist for Ember Resources

With the clock ticking for project approval and government funding, Ember called in a Waukesha team of experts to provide engineering and technical support to upgrade ten 7044 VHP Series Two GL and GSIs to Series Four and Series Five specifications. In addition, the team navigated the governmental regulations, even helping with the program application.

To be able to lower emissions and have the Waukesha guidance to navigate Alberta’s programs was top-notch support. The operational benefits make the upgrades an all-around win.

Jay Befus, Emissions Compliance and Rotating Equipment Specialist for Ember Resources

Ember installed the first Series Four and Series Five upgrades in Q4 2020 and immediately recognized a difference. INNIO estimated the upgrade would reduce Ember‘s CO2e emissions by 10 million metric tons while increasing its service interval extensions by 20% to 25%. Savings on fuel and oil consumption were a bonus.

In addition to significant stack emissions reductions, the Waukesha VHP engine conversions have proven a decrease in fuel consumption and increased reliability. This has contributed to a realized reduction to both operating and maintenance expenses. The addition of Series Four and Series Five engines to Ember’s fleet has not only had a positive impact to the environment, but to our business as well.

Jay Befus, Emissions Compliance and Rotating Equipment Specialist for Ember Resources

10

engines upgraded to Series 4 & 5 specifications

10

million less metric tons of CO2e

20-25%

service interval reduction

Obviously, this upgrade will have many lasting operational and environmental benefits that will continue for years to come.